constant air-fuel ratio is maintained due to vacuum depression choke valve is provided in the air circuit for cold starting multiple venturies result in better formation of the mixture at very low speeds causing steady and smooth operation at very low and high engine speed has triple venture diffusing type choke in which smallest lies above the level float chamber, other two below the petrol level, one below other. diaphragm type acceleration pump is used for increasing speed case well of emulsion system is used for idling and slow running condition used in Fiat and standard cars and Willey jeep provide ease of starting, good performance, and reliability Horizontal or downdraught: mixture is assisted by gravity in its passage to the engine induction spring loaded by-pass choke is used in higher speeds Carburettor types: butterfly type valve or choke is used between the entrance to the carburettor and venture throat to meet the requirement Rich mixture is required during cold starting period, at low crancking speed and before the engine warmed up condition acceleration pump of spring loaded plunger is used for fuel supply. Engine acceleration condition or rapid increase in engine speed may open the throttle rapidly which will not able to provide rich mixture It has meter rod economizer of large orifice opening to the main jet as the throttle is opened beyond a certain point

this system provides the richer mixture for maximum power range of operation (iii) Power enrichment or economizer system: gradual opening of throttle may stop the idling jet consists of small fuel line from the float chamber to a point of throttle side Idling jet is added for the idling and low load operation which requires rich mixture sof about A/F ratio 12:1 opening of butterfly allows more air inductance which decreases quantity of fuel drawn Allows more admittance more additional air and the mixture is not over rich Valve spring of auxiliary valve lift the valve during increase of engine load which increases the vacuum at venture it creates pressure differences according to engine operating conditions in this arrangement large vent line connects the carburetor entrance with the top of the float chamber and another small orifice line is connected with the top of the float chambers with venture throat

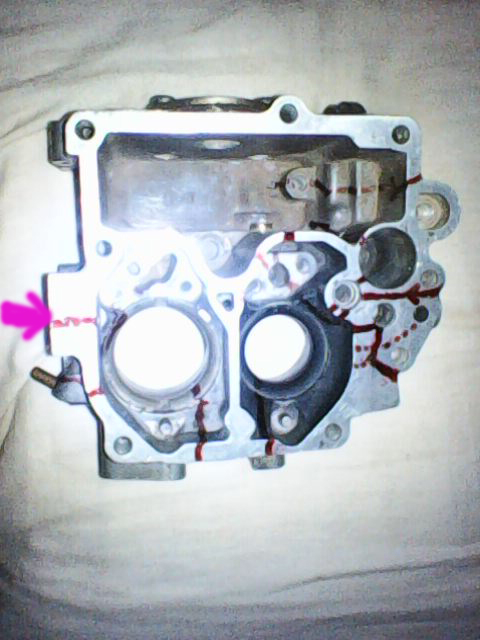

in this arrangement main metering jet is fitted about 25 mm below the petrol level which is called as submerged jetīack suction control or pressure reduction method: mixture correction is done by air bleeding alone Addition to the main jet, a compensating jet is provided to provide the leanness effect

0 kommentar(er)

0 kommentar(er)